- #Cnc usb controller mk1drv drivers#

- #Cnc usb controller mk1drv driver#

- #Cnc usb controller mk1drv manual#

- #Cnc usb controller mk1drv upgrade#

Provides ENABLE signal to the motor driver. Provides DIR or DIRECTION signal to the motor driver. Provides a STEP signal of minimum 12 us pulse width to the motor driver. The 5VEXT jumper, highlighted above, must be closed to enable this feature.

#Cnc usb controller mk1drv drivers#

+5VEX: STEP: DIR: ENABLE: GND: Motor drivers can be powered from the USB controller. Pins 2,4, 6,7, 8 and 10 provide the Ground or common side of connections. 6Ĩ 2.2.1 Mk1 MOTOR connector Each connector controls one motor driver.

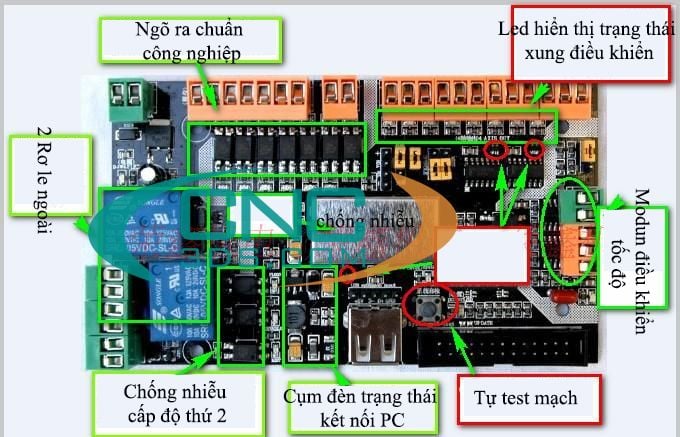

When external power supply is used: Mk1-4 Axis Controller hardware requires 5V DC supply Power supply should be at least 200mA. When the USB CNC Controller is configured to use external power, it is recommended that the USB port is NOT connected if no external power supply is present. IMPORTANT: The controller can be powered in several ways, including use of an external power supply. This aids the construction of longer cables and ensures plug-in connections correspond to the USB CNC Controller pin outs. For maximum flexibility in controller layout, a ribbon cable and plug kit is available. A DB25 adapter is available, for motor drivers requiring this form of input, with male or female DB25 connector. Use of a screw terminal adapter makes connection to the type of drive in the image much easier. Optional support hardware can be employed to customize installation to suit user requirement. The USB CNC controller is compatible with the vast majority of motor drivers that use step/direction signals.

#Cnc usb controller mk1drv manual#

generated G-code Profili 4-axes and 3-axes G-code supported import toolpath from DXF files import toolpath from PLT/HPGL files import toolpath from image files import toolpath from NC-Drill (Excellon) files import toolpath from Gerber (RS-274X) files toolpath simulation automatic homing procedure automatic tool length measuring advanced toolchange procedures export toolpath to G-code export toolpath to DXF SDK (software developers kit) is available works on MacOS X (Snow Leopard ) with virtual machine emulating Windows XP SP3 Mk1-4 axes USB CNC controller 25 khz maximum step frequency 3 digital outputs (flood, mist, spindle) 12 us minimum pulse width manual jog input keys for all axes limit keys for all axes control external devices with I2C protocol 4ĥ 1.3 System Requirements Minimum system requirements: 1 GHz or faster processor 512MB RAM 500 MB available hard disk space Graphics with OpenGL support USB 2.0 Framework 3.5 SP1 Recommended system requirements: 2 GHz or faster processor 2GB RAM 500 MB available hard disk space Graphics with OpenGL support USB 2.0 Framework 3.5 SP1 5Ħ 2 Hardware 2.1 Installation Installation of PlanetCNC CNC USB Controller requires a USB equipped PC or laptop along with motor drivers appropriate to the motors in use.

#Cnc usb controller mk1drv driver#

3Ĥ 1.2 Features and specifications: USB (V2.x) from PC/Laptop running Windows XP, Vista or Windows 7 (32 bit or 64bit) motor driver connector pin-out is compatible with 10 pin open source interface controller works with most step/dir motor drivers available on the market buffered IO for maximum performance advanced interpolation algorithms start, stop, pause and resume execution of program on your machine standard RS274/NGC G-code (EMC2 compatible) advanced G-codes - G40, G41, G42 (Cutter Radius Compensation) supported advanced G-codes - G43, G49 (Tool Length Offsets) supported advanced G-codes - G54, G59.3 (Coordinate System Origins) supported tested with SolidCAM, MasterCAM, ArtCAM, Vectric. It has many advanced features to assist day-to-day CNC machine operation. The USB CNC Controller software is a dedicated application, designed to fully exploit the features of the purpose-built hardware. Additional machine control software is NOT required.

PlanetCNC controllers provide a complete, fully integrated software/hardware solution.

#Cnc usb controller mk1drv upgrade#

They can serve as direct replacement or upgrade for many parallel port break-out boards. The controllers use the USB port, available on all modern computers and laptops. 3 1 Introduction 1.1 Overview The PlanetCNC series of USB CNC motion controllers link between a personal computer and motor drivers supporting step/direction control.

0 kommentar(er)

0 kommentar(er)